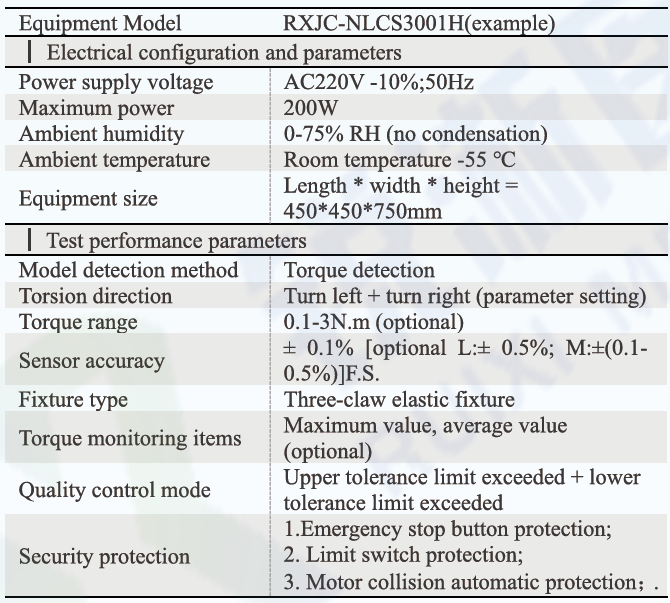

The equipment is integrated with high-precision imported torque sensor, precision linear module, high-torque low-speed torque drive motor, Mitsubishi PLC, human-computer interaction touch screen, elastic finger fixture and other institutions. The product is placed in the corresponding mold base groove, the linear module drives the elastic finger to move up and down the work position and exit the work position, the parameter setting finger moves down to the test position, the finger is stuck in the sleeve flange groove, the low-speed high-torque motor drives the sleeve to make a twisting movement, and the parameter sets the twisting angle or number of turns. The internal device of the mold base is equipped with a precision torque sensor, which detects and displays the torque value in real time in the human-computer interaction screen during the twisting process. After the twisting is completed, the internal program automatically calculates and captures the maximum torque and average torque (optional) values, and automatically evaluates whether the product under test is qualified according to the range of maximum and minimum values set by the parameters: qualified product, the screen displays "test passed", and the green indicator light at the top of the top of the top of the top of the top of the equipment; unqualified product, the screen shows "test out of tolerance" and the red indicator light on the top of the device is on.

A company specializing in bionic fatigue testing

and suppliers of laboratory equipment

Service tel:021-52238601

E-mail:taylor_zhou@ruiximed.com

Add.: Room 101,102,Kechuang Building, No.1588, Lianhang Road, Minhang District, Shanghai

Wechat official account