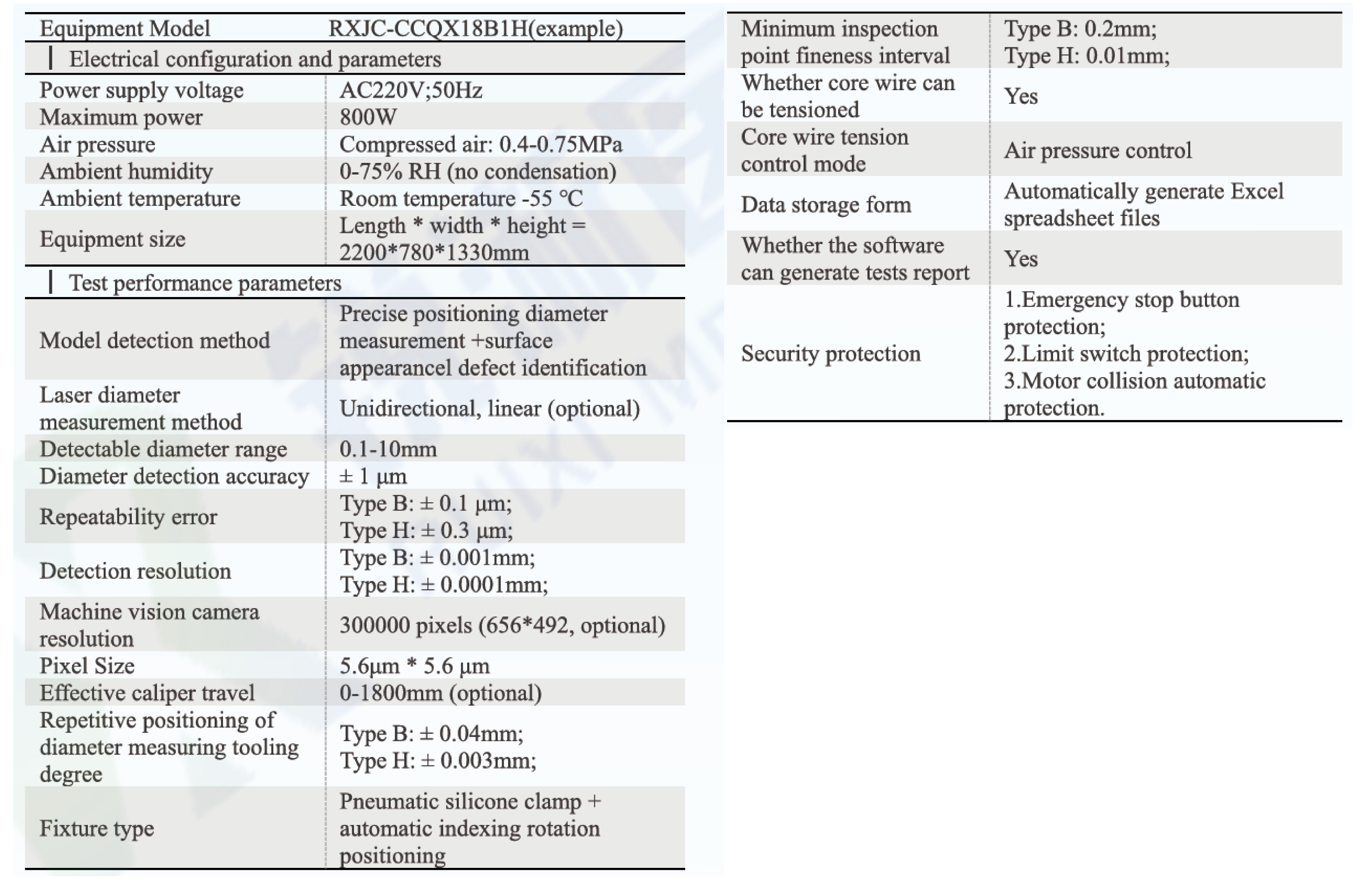

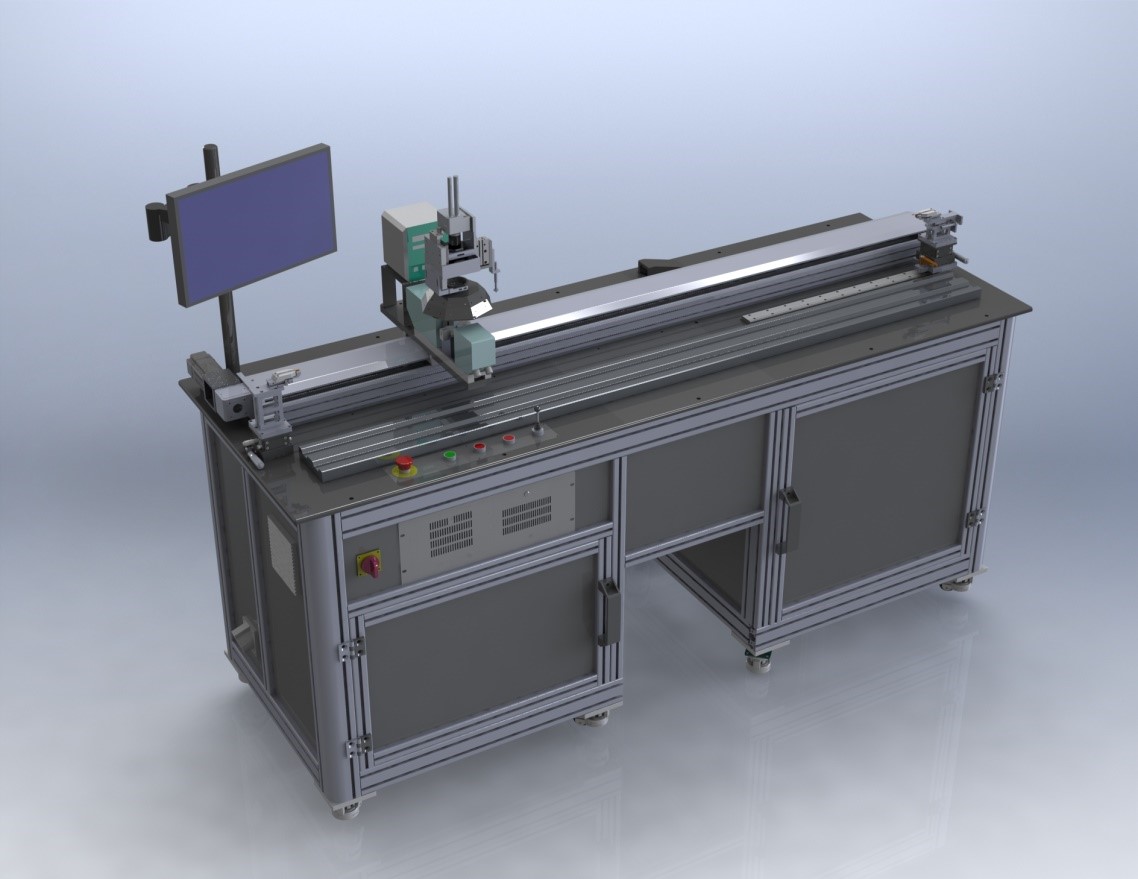

The equipment integrates high-precision laser calibrator, high-rigidity ultra-long stroke precision linear motor (linear module), industrial control machine, high-resolution industrial camera, micro distortion telecentric industrial lens, high-speed data sampling integrated circuit. Through the industrial control machine machine program control, precise positioning, to achieve any length of catheter, guide wire, sheath tube, optical fibre, enameled wire, precision shafts, micro-drawing, tubes, rods, and other products of any length of the axis of any point of the direction of the diameter of the test and the product surface of the real-time photography and defects automatically identify the function of the detected data and positional relationship data into the "displacement diameter" curve, and will be identified defects in the location of the picture is automatically saved to the corresponding folder, in order to generate the specified format of the data report file and the detection of defective products.

A company specializing in bionic fatigue testing

and suppliers of laboratory equipment

Service tel:021-52238601

E-mail:taylor_zhou@ruiximed.com

Add.: Room 101,102,Kechuang Building, No.1588, Lianhang Road, Minhang District, Shanghai

Wechat official account